PRECISION

AND INNOVATION

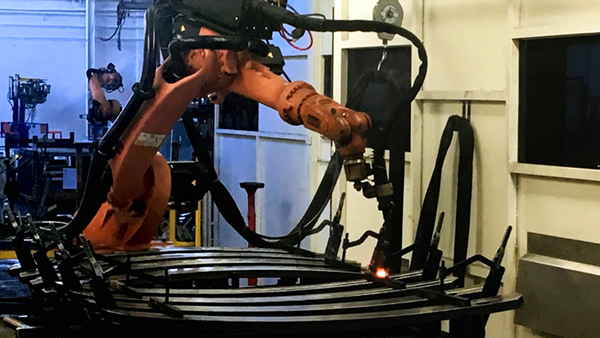

We have a modern sheet metal processing department for aluminium and special steel, that can complete the entire production cycle.

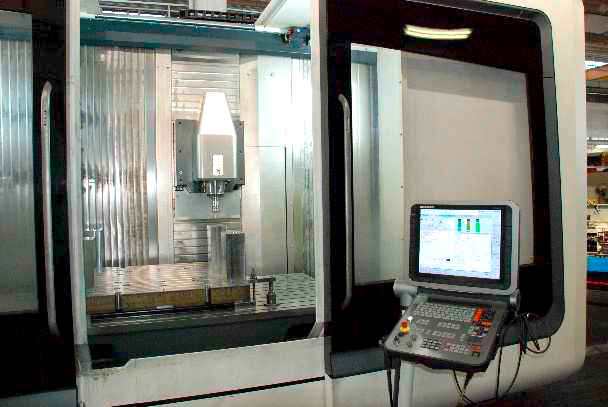

The department is equipped with more than ten operating machines with CNC milling centers.

The main working areas are: milling, drilling, threading, cutting, moulding, bending.

In addition, the department performs the washing, barrel finishing and cleaning of the machined products.